Lange 31 - The Key System

Part 3

Tony de Haas showing where on the movement the remontoir is located. Note the movement is an unfinished movement which works perfectly, but without final finishing.

The remontoir spring is never fully depleted, and is pre-tensioned, this allows the watch to restart when it is stopped under the tension of the remontoir. A stop-clock mechanism is also fitted, to allow the watch to be stopped for precise time adjustment.

The mainspring is so powerful, that it presents another problem...winding it would be a chore...if the gearing of the crown is high, it would take a very long time to wind the watch. Using a ratchet wheel to keep the winding power similar to a Lange 1, it would need 150 turns to completely wind the mainspring. Not very practical. Or one could device a low gearing, and require a few turns. But the power to wind this crown would be impractical.

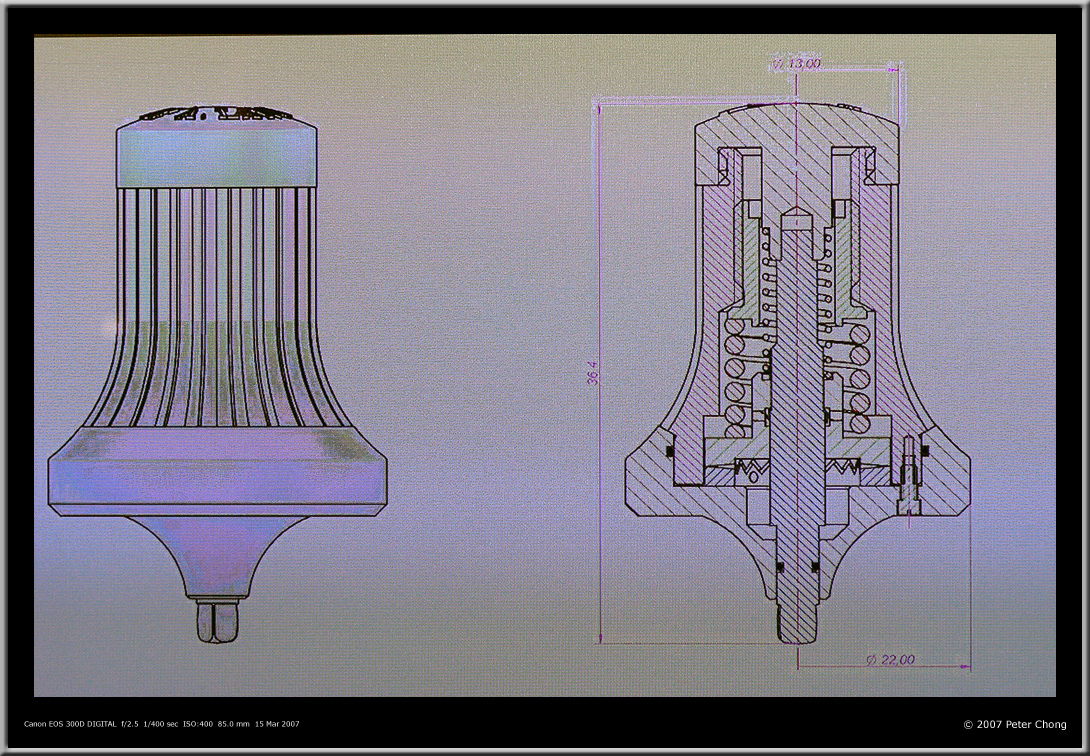

The Lange engineers came up with a twist to solve this...they chose a low gearing - only 31 turns required to fully the watch. A special key is designed with a large thumb crown to afford the leverage to wind it.

Like the rest of the Lange 31, there is more than meets the eye with this key. The design is complex because it incorporates a ratchet mechanism and torque limiter.

The key is machined out of stainless steel, and like a typical Lange product, is beautifully finished. Two keys are provided.

Picture below shows the key next to the Lange 31. In the background is the Datograph, as a comparison of size.

Detail showing relative locations of the remontoir (A) and the key (B)