A visit to Northampton, and the Edward Green Factory

By Peter Chong

The

boot of our car after an afternoon’s shopping in Northampton. Final count – 2

pairs of Edward Greens, 5 pairs of John Lobbs. What a success!

As a detour from a trip I made recently leading a group of watch enthusiasts to the Lange Uhren factory in Glashutte, Germany, I spent the weekend with a good friend in London. We spent the afternoon in gentlemanly pursuits of browsing the stores in Jermyn Street and at the Burlington Arkade, before spending the evening at Ronnie Scotts with some great Jazz. We hired a car, and went shopping in Northampton on Monday…ended up with the above spoils.

First off the Edward Green Factory. We called the factory ahead, and secured an 11am spot with our hostess – Susie Jones. She met us cheerfully at the door, and showed us around.

The first room we came to, we saw

a team of men cutting leather. The

process, known as clicking was performed by a highly skilled workman who would

cut the individual pieces of leather into patterns.

We were told that all clicking for Edward Green was done at

this place.

The picture above shows a master clicker, placing pieces of leather on his pattern (which, as shown is a piece of green cardboard).

The patterns were then stiched together in these huge sewing machines, like those your mother would use for mending clothes, as shown above.

A machine was used to make the perforations in the brogue.

Next, we went to visit the man with the lasts. Here all the

lasts were stored.

The swen uppers were then stretched over the last like so. At this stage, the shoelaces were nothing more than pieces of cloth:

The upper is then nailed onto the last, with temporary

nails:

An iron wire is then lopped over the last, and pulled into place, stretching the upper over the last. A machine is used to do this:

Then, the nails are removed, and the shoe/last looks like

this.

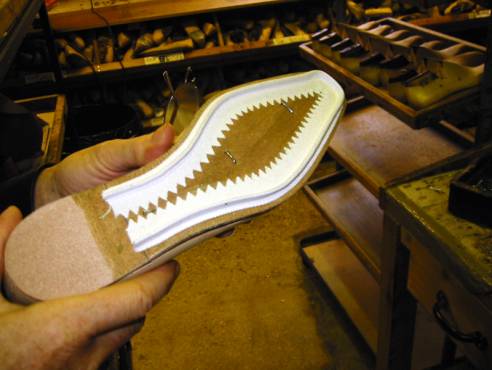

Another team, in the meantime, prepares the soles, but

glueing in the feather:

The shoe was then put into a Goodyear welting machine, which did the stiching of the welt, semi-automatically. The operator puts the upper/sole on, clamps it tight, and off the machine goes at a furious pace, finishing the complete welt in less than 20s:

After welting, the inner side is then filled with cork bits:

And the shoe is then sent for installing the sole.

Backtracking upstairs, we came across these two gentleman,

who were in charge of “skin stitching” the aprons and center toe seams. First,

the thread is prepared by waxing:

Then, the aprons are stitched using a boar’s bristle. From what I can see, using a boar’s bristle, due to the ability of the bristle to flex, gives a smoother finish on the raised apron than can be achieved with a steel needle.

Back to the shop floor, the outersoles are glued, and stitched

on, leaving the thread inside the channels. The shoes then wait with the

channels open:

The channel is then closed:

The heels are nailed on:

And the final finishing at the factory floor, the soles are cleaned, and a hot iron is used to apply polish to the edges:

The shoe is then sent to the finishing department, where skilled craftsmen select the final color of the shoe, and finish it to their specifications:

|

|

|

|

|

|

And the final beautiful shoe….um…shoes…any guess which one

is the Edward Green?

©Peter Chong, March 2004.