|

|

|

|

|

|

|||

|

TZWS Class: Level 1E - Lesson 1 - Part 3

PICKING THE CORRECT DRIVER FOR THE SCREW AT HAND For each screw there is only one correct driver, and much of the damage caused to watches during service is caused by the use of incorrectly sized (or damaged) drivers. It is not possible to tighten a steel screw with a steel blade and leave no evidence of work when viewed at high levels of magnification. But the evidence should most certainly not be visible to the naked eye, and probably not visible up to 4X magnification. Four power magnification is a reasonable standard for excellent quality work.

As shown below, a properly sized driver fills the slot without overhanging it. It is held perpendicular to the slot so that the face of the tip sits flat in the groove and upright. The screw is firmly snugged without over-tightening. Screwdriver tips must be kept in good condition and properly shaped. Damaged tips should be reshaped, or discarded and replaced.

OTHER TOOLKIT ITEMS

The movement

cover (6, below right) is used to cover a movement (or movement on a

holder) when it is not being worked on. Develop the habit of always covering

the movement with the cover--or a laying a piece of watch tissue over

it--whenever

The Rodico (8)

is a cleaning putty usually used in tiny pieces torn from the "log." Rodico

will absorb excess oil, lift lint, and remove fine debris from parts and

movements. While it may be used to clean a movement plate after a movement

is reassembled, be careful not to force it down into jewel settings, as it

will remove the fresh oil. Simply blot or wipe it over the upper surface

of the jewel setting without pushing it down into the setting. Rodico is

especially handy used on the tip of a piece of peg wood. It may be rolled on

the work surface to a fine point

Two Bausch &

Lomb in-the-eye loupes are supplied in the TZWS toolkit for non-eyeglass

wearers, a 4-power (10, above right ) and a 10-power (9).

For eyeglass wearers a combination Behr loupe with the same powers is

provided. Most work is done with a 4-power. It provides adequate depth of

field (front-to-back focus), a wider field, and enough magnification for

most watch work. The 10-power allows more careful inspection of parts, and

is useful for escapement work, including shock assemblies, balance springs,

and regulators. It can be used for some routine work, but is tiring in

The two millimeter peg wood sticks (11, a bundle of 25 is supplied) have a variety of uses. They can be cut on an angle or sharpened to a point with a razor for cleaning parts of sticky debris. They can be used uncut with Rodico as illustrated above left . They can be used with a bit of oil and polishing compound for fine polishing of pivots and other parts. They are also handy for supporting and manipulating parts when a steel tool might mar a surface. As with Rodico, the versatility of peg wood is almost unlimited. While they are resistant to shedding, they will leave some debris behind when used with pressure, and this should be removed with the dust blower or a small piece of Rodico.

The pith wood

disc (12 ) is a staple of the watchmaker's toolbox. Screwdriver's,

tweezers, and oiling needles should all be routinely cleaned before applying

them to a movement by jabbing them into the pith wood. The pith wood absorbs

oil, dirt,

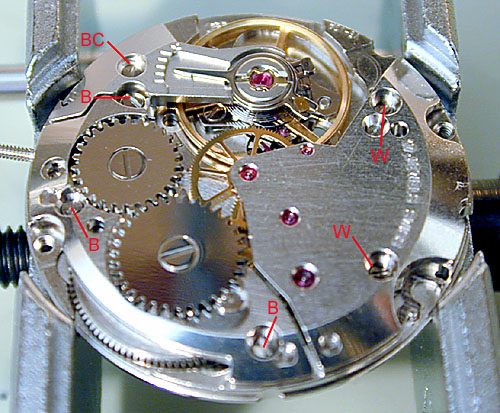

Item 13 is our Fontainemelon caliber 97. It will be discussed at the end of this Lesson. Item 14 is a piece of lintless watch paper which is supplied in the TZWS toolkit in a box of 1,000 sheets. Watch paper should be used when handling movements, and under movements or case parts placed on the work surface. It may be used as a temporary cover on top of parts sitting in the open, and used to wrap dials, hands, and other delicate parts for storage. Watch paper is also useful for absorbing excess lubrication from newly-greased case gaskets, mainsprings, and other large parts. Watch paper is indispensable to the careful practice of watchmaking. A DEXTERITY EXERCISE The screwdriver and tweezers are the basic tools of the watchmaker. It is worth spending a bit of time developing simple dexterity in handling them. As illustrated below, the ETA caliber 2801 uses two screws to attach the wheel train bridge (W), and three for the mainspring barrel bridge (B ). The single screw holding the balance cock is marked BC.

It is suggested that you do not remove the balance cock screw (BC) at this time in order to avoid possible damage to the balance assembly. The other five bridge screws can, however, be removed and replaced one at a time. You will find that the 1.2 millimeter (120, red) screwdriver fits them properly. With the movement mounted in the movement holder, unscrew one screw at a time. Pick it up with the #2 tweezers, without scratching the movement plate. Place the screw on the work surface, pick it up again, and replace it. Repetition of this exercise several times with all six screws will begin to familiarize you with the motor skills for handling small parts. Refer to sections earlier in this lesson on the handling of screwdrivers and tweezers. As you work, notice the construction details of the bridges you are working on. With Lesson 1.2 we will begin study and full disassembly of the 2801. In the meanwhile, happy watchmaking!

|

|||||||

|

Copyright © 2001-2004 A Bid Of Time, Inc., All Rights Reserved | |||||||

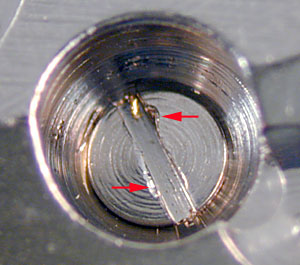

Both

screws and screw drivers must be hardened sufficiently to do their work, but

not made so hard that they become brittle. This means that the screwdriver

must be slightly harder (and thus more brittle) than the screw it works on:

otherwise the driver would distort before the screw, and the screw would

break before the driver tip. Thus, the slightly harder driver tip will leave

some evidence of compression in the softer steel of the screw. In the

illustration left, at 35X magnification, we see the result of factory

assembly on the ETA 2801 (arrow ). Final tightening of this 1.2 mm

bridge screw has compressed and slightly distorted the edges of the slot.

This is reasonable damage and cannot be avoided with correctly hardened

steel.

Both

screws and screw drivers must be hardened sufficiently to do their work, but

not made so hard that they become brittle. This means that the screwdriver

must be slightly harder (and thus more brittle) than the screw it works on:

otherwise the driver would distort before the screw, and the screw would

break before the driver tip. Thus, the slightly harder driver tip will leave

some evidence of compression in the softer steel of the screw. In the

illustration left, at 35X magnification, we see the result of factory

assembly on the ETA 2801 (arrow ). Final tightening of this 1.2 mm

bridge screw has compressed and slightly distorted the edges of the slot.

This is reasonable damage and cannot be avoided with correctly hardened

steel.  The

same screw is shown left after incorrect tightening. Here we

see not simply compression of the metal, but damage caused by

over-tightening, with the driver tip slipping up and out of the slot. The

driver was also too small for the slot, and damage is concentrated towards

the center of the slot. This kind of damage is a result of sloppiness, and

will give a movement a shabby, mistreated appearance when repeated

throughout the work. Correct positioning of the correctly-sized tip and

correct torque prevent such damage. Positioning and torque are learned with

experience, and become natural and intuitive with time. Selection of a

correctly sized driver is simply a matter of attention and care.

The

same screw is shown left after incorrect tightening. Here we

see not simply compression of the metal, but damage caused by

over-tightening, with the driver tip slipping up and out of the slot. The

driver was also too small for the slot, and damage is concentrated towards

the center of the slot. This kind of damage is a result of sloppiness, and

will give a movement a shabby, mistreated appearance when repeated

throughout the work. Correct positioning of the correctly-sized tip and

correct torque prevent such damage. Positioning and torque are learned with

experience, and become natural and intuitive with time. Selection of a

correctly sized driver is simply a matter of attention and care.  Shown

right is damage caused by too large a driver. The ends of the tip

have overhung the screw and gouged the edges of the bevel (decouverture)

around the screw hole. Below right is a screw damaged by too narrow a

blade.

Shown

right is damage caused by too large a driver. The ends of the tip

have overhung the screw and gouged the edges of the bevel (decouverture)

around the screw hole. Below right is a screw damaged by too narrow a

blade.

The

movement holder (Bergeon No. 4040) is a simple, excellent device that makes

work much easier and protects each side of the movement while the other is

being worked on. A movement always has a cannon pinion or center wheel

pinion protruding from the dial side. For this reason, an uncased

movement cannot be laid face down on the dial side. The movement holder is

adjusted with the thumb screw, and the movement can be placed at different

levels in the holder ( below right, blue arrows). The movement should

be placed so that all movement edges rest on the same "step" of the holder.

The upper step generally gives better access to the edge of the movement,

but is somewhat less secure. Once the movement is placed, the holder is

tightened only to snugness with the thumb screw.

The

movement holder (Bergeon No. 4040) is a simple, excellent device that makes

work much easier and protects each side of the movement while the other is

being worked on. A movement always has a cannon pinion or center wheel

pinion protruding from the dial side. For this reason, an uncased

movement cannot be laid face down on the dial side. The movement holder is

adjusted with the thumb screw, and the movement can be placed at different

levels in the holder ( below right, blue arrows). The movement should

be placed so that all movement edges rest on the same "step" of the holder.

The upper step generally gives better access to the edge of the movement,

but is somewhat less secure. Once the movement is placed, the holder is

tightened only to snugness with the thumb screw.  The

Bergeon dust blower (No. 4657), below left, will prove to be your

best friend--and, if you are not careful with it, your worst enemy. Used to

blow dust and debris from parts, movements, and cases, it is indispensable.

But it will easily roll on your work table, crushing and dispersing parts in

its path into the Bermuda Triangle. Too strong a puff on a balance spring

and the spring can be destroyed, twisted and tangled beyond recognition. I

use a small cup to hold the blower

The

Bergeon dust blower (No. 4657), below left, will prove to be your

best friend--and, if you are not careful with it, your worst enemy. Used to

blow dust and debris from parts, movements, and cases, it is indispensable.

But it will easily roll on your work table, crushing and dispersing parts in

its path into the Bermuda Triangle. Too strong a puff on a balance spring

and the spring can be destroyed, twisted and tangled beyond recognition. I

use a small cup to hold the blower

when

not in use (to keep it from rolling) and always return it to its home

when not using it. When pointing the blower at the balance and balance

spring, puff very gently.

when

not in use (to keep it from rolling) and always return it to its home

when not using it. When pointing the blower at the balance and balance

spring, puff very gently.  you are not working on it. The two covered, compartment trays (7 )

are used to hold parts that have been removed from the movement. They keep

the parts clean and allow you to organize related parts in the same

compartment for ease of identification and reassembly. With both covers and

parts trays, it is a good idea to blow them out immediately prior to use.

you are not working on it. The two covered, compartment trays (7 )

are used to hold parts that have been removed from the movement. They keep

the parts clean and allow you to organize related parts in the same

compartment for ease of identification and reassembly. With both covers and

parts trays, it is a good idea to blow them out immediately prior to use.

and

used for very detailed cleaning. Be careful when forcing the Rodico under

high pressure into small spaces, for it may break off and be difficult to

remove. Should this happen, use another piece of Rodico to try to remove it.

Rodico is also useful for cleaning tools, usually by simply jabbing the tool

into a larger piece.

and

used for very detailed cleaning. Be careful when forcing the Rodico under

high pressure into small spaces, for it may break off and be difficult to

remove. Should this happen, use another piece of Rodico to try to remove it.

Rodico is also useful for cleaning tools, usually by simply jabbing the tool

into a larger piece.  continuous

use because of optical limitations. In-the-eye loupes are available up to

approximately 18X, beyond which shake and optical limitations make them

unusable.

continuous

use because of optical limitations. In-the-eye loupes are available up to

approximately 18X, beyond which shake and optical limitations make them

unusable.  and

debris and prevents transfer of these contaminants to the movement. With

tools used to handle or lubricate balance jewels, pith wood is preferable to

Rodico for tool cleaning because the pith wood will provide an absolutely

oil-free tool. After a tool is cleaned in pith wood, it may require a puff

from the dust blower to remove tiny particles of pith wood clinging to the

tool.

and

debris and prevents transfer of these contaminants to the movement. With

tools used to handle or lubricate balance jewels, pith wood is preferable to

Rodico for tool cleaning because the pith wood will provide an absolutely

oil-free tool. After a tool is cleaned in pith wood, it may require a puff

from the dust blower to remove tiny particles of pith wood clinging to the

tool.