|

The Seiko Spring Drive: Innovation and Refinement, Part 3

A Visit to the Seiko Epson Factory, in Shiojiri, Nagano prefecture

Upon completion of our meeting with the Seiko Watch Corporation

executives, we caught a train at Shinjuku station – destination: the

town of Shiojiri in the mountains of Nagano prefecture. Nagano,

of course, was the location of the 1998 Winter Olympic Games, but is

also the home of the Seiko Epson division of the Seiko Corporation.

Sunset in Suwa City, Nagano Prefecture. Home of the Seiko Epson

Corporation.

Seiko Epson is one of the "prime contractors" for

Seiko Watch Corporation's model production - the other being its sister company,

Seiko

Instruments. While the headquarters for

Seiko Epson are found in Suwa

City, the factory which makes high-end

Spring Drive, Grand Seiko, and Credor watches for the Watch Operations Division, is

located in

the town of Shiojiri,

a short distance away.

Ordinary looking from the outside,

Seiko Epson’s watch factories stand tall in

horological

history – this was the birthplace of the first Japanese automatic watch

(1959),

the first quartz wristwatch (1969), the winner of the last Swiss

Observatory

Mechanical Chronometer Competition (1969), the first LCD wristwatch

(1973), the

first

autoquartz (“Kinetic”) watch (1987), and the world’s thinnest quartz

movement

at 0.85mm (1989). Currently, this factory

serves as the only location where Spring

Drive movement and final watch assembly is performed.

A Technical Briefing at Seiko Epson - (l to r) - Takeo Murata, Kaoru

Iida, Tatsuo Hara, Junya Kamijo

After

a welcome by Mr. Kaoru Iida, General Manager of the Watch Brand

Department, we are given a technical

briefing and demonstration of the Spring Drive mechanism by Mr. Tatsuo

Hara, who

was one of the developers of the Spring Drive technology working with

Yoshikazu

Akahane. Mr. Hara gave us a detailed description

of how the Spring Drive movement works, using the Tri-Synchro Regulator

in place of the traditional lever escapement.

Tatsuo Hara Demonstrates the braking of the Glide Wheel of the

Tri-Synchro Regulator

In addition to the

Tri-Synchro Regulator, the innovative Magic Lever winding system

originally

developed in 1959 is also demonstrated.

This bi-directional dual-pawl winding system is both simple and

efficient – and in Spring Drive trim is 30% more efficient than

traditional

click-wheel based automatic winding systems. (Ron

DeCorte will soon be sharing an

in-depth investigation of a pre-production prototype of the movement,

including both the Tri-Synchro Regulator and the Magic Lever.

However, allow

me to give a small preview - the theory and implementation of the

Spring Drive is

both

elegant and ingenious.

After the briefing, we are led on

a tour of the actual

workshop facilities. Seiko Epson has only

five watchmakers who they have certified to perform final assembly and

checking

of the Spring Drive movement – Mr. Junya Kamijo, Ms. Satomi Nakajima,

Ms.

Toshie Tokunaga, Mr. Hitomi Sakai, and Ms. Kaori Washimi.

All have distinguished themselves in national

and international watchmaking skills competitions.

Junya Kamijo, Manager, Watch Technical Engineering Workshop, works on

the Spring Drive Automatic

In the Takumi (“Master”) Studio area,

we are led by a series

of glass windows enclosing the movement assembly and component build-up

areas. The air conditioning and lighting

systems are specialized, to ensure a clean environment for the watches

and optimum vision

for the watchmakers.

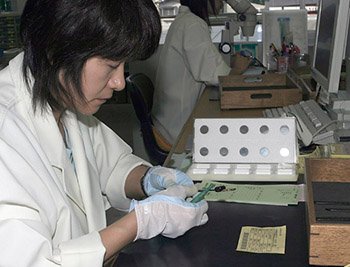

Jeweling of a Spring Drive base plate. The actual setting of

parts is performed by hand, not machine

The watchmakers all

wear white lab coats, and use finger cots or gloves to ensure that

their skin

oils do not contaminate movements, cases, or dials.

Much of the small-scale work is performed

under binocular microscopes rather than loupes.

While there

are plenty of computerized devices in use (e.g. computer

controlled

positioning of a base plate that is being jeweled, measurement of

jewelling

depth, etc.), all of the actual building and assembling is done by hand. Each of the five Spring Drive watchmakers is

responsible for the complete assembly of the movement from start to

finish, in

order to ensure high quality.

A Credor Skeleton Manual Wind Masterpiece

(Click here for a larger photo)

Downstairs

from the Takumi Studio

is the machining area

where dials and hands are manufactured. Again,

the machines are operated by hand and parts are

inspected by eye via microscope, instead of relying on automation.

This craftwoman makes applied markers for dials, driving the machinery

by hand

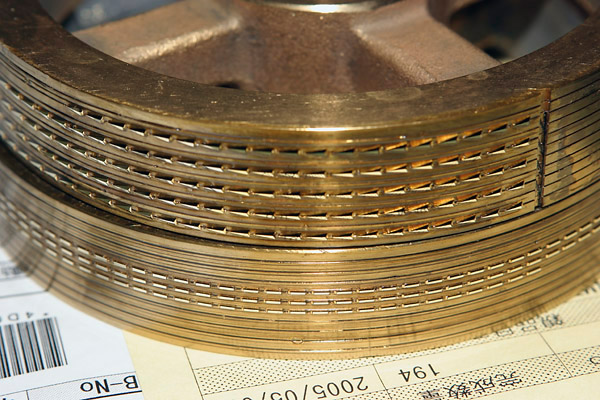

Gold Wire attached to a spinning drum is machined down to form indicies

The Making of Hands

Next to the dial and hands

manufacturing area is the Micro

Design Studio, where gold and platinum jewelry watch cases are shaped

and inlaid

with stones, again all by hand.

Setting of a Gem in a Jewelry Watch Case

Careful With that Diamond!

Cutting and Setting Another Diamond Case

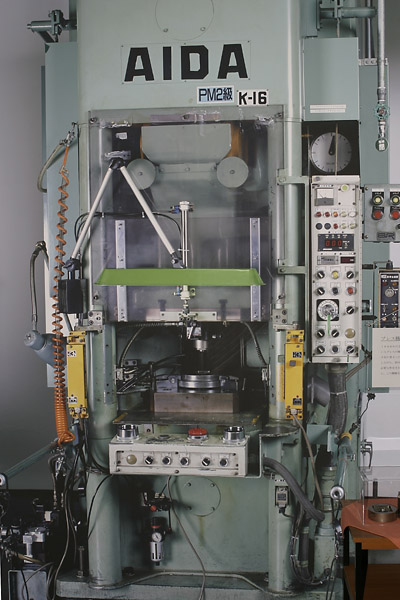

We were unable to tour the actual case

making facility (which

is part of this factory), but were shown life size photos of the

machinery used

to make the case blanks from raw materials.

A Case Making Press

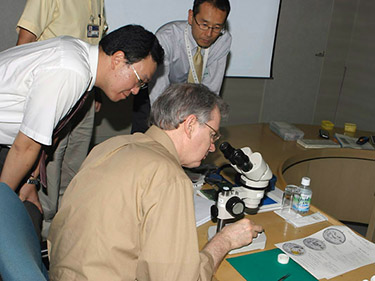

Our tour wrapped up with an opportunity

for your reporter to

get a feel for working with the Seiko movements. We

were each given an actual Spring Drive

Automatic movement, a few basic watchmaking tools, and a

binocular

microscope, and were instructed on the disassembly and reassembly of

the winding rotor and

automatic

winding bridge.

Ed Hahn (left) and Joe Thompson (right) try to become

Spring Drive watchmakers. They do not succeed.

Suffice to say, Seiko Epson did not certify a

sixth

watchmaker for the Spring Drive assembly line.

Indeed, one hopes that the planned 1,000 watch sales target does

not have

to be reduced to 996. However, I am

proud to say that I was at least able to successfully complete all

steps of the

process.

(top row l to r) - Kenkichi Shibata, Tatsuo Hara, Junya

Kamijo, Hiroshi Kamijo, and Bill Shuster (JCK).

(bottom row l

to r) - Kaoru Iida, Jordan Rothacker (IWW), Ed Hahn (TZ),

and Joe Thompson (Watchtime).

To top off a very busy day, our hosts at Seiko

Epson put us

up at a traditional Ryokan hotel in Suwa city, and fed us a wonderful

Japanese

dinner. Throughout the trip, our hosts

were

extremely

gracious and truly made us feel very welcome. Yet,

none of this was

really surprising, as the same attention to detail given to us as

visitors

is

reflected not only in the construction of the new Spring Drive watches

that will be

introduced this

fall, but is also characteristic of the Japanese people and culture.

I would like to especially thank Mr. Tadaaki

Ohira, who was

our organizer, tour guide, shepherd, and impeccable host during our

visit. (He didn't get the watchmaking job, either.)

The official Seiko Spring Drive website is:

http://www.seikospringdrive.com

Click here to return to Part 2

Click here to return to Part 1

Click here to return to the TimeZone Seiko Forum

|