|

Vianney Halter by Ron DeCorte July, 2004

The village of St. Croix Switzerland sits atop a mountain at about 1,000 meters (3,000+ feet) in the Jura range just inside the Swiss border and a stone throw from France. Arriving in March is always uncertain, it can change between spring and winter, and back, from minute to minute. In the case of my recent visit it did a lot of both. Vianney Halter left Paris about 15 years ago to work as a restoration expert in St. Croix and later started his own company. I remember visiting him early on at his new factory, it was a very small operation of two or three people in those days compared to the 12+ he employs today. But some things never change. Vianney is a warm, passionate, and gracious person with an expansive amount of enthusiasm for the creation of his watches. Nobody is allowed to pass the front door at the Vianney Halter ateliers unless they have a smile on their face, good intentions in their heart, a joke or two on their tongue, and a passion for watches doesn’t hurt either (but not compulsory)!

The Vianney Halter ateliers are located on three floors of this building that is entirely devoted to watchmaking, from A to Z.

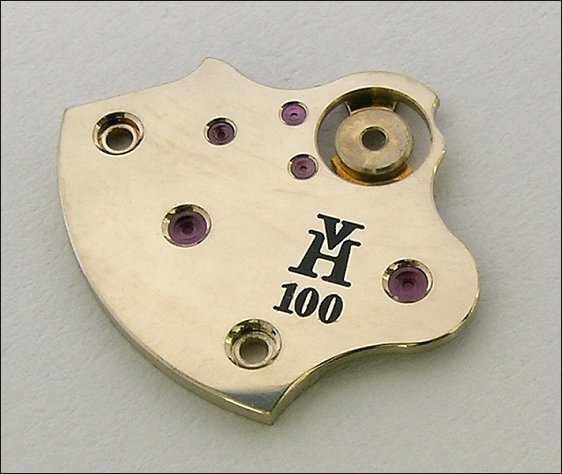

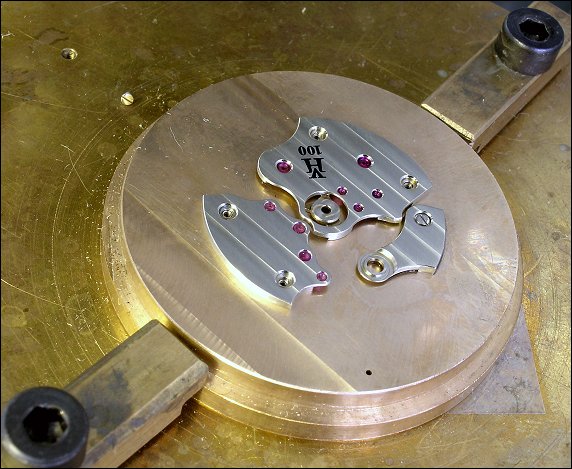

A finished “Classic” main-plate, decorated, jewels set, and ready for assembly.

Some of the wheels used in the “Classic”. Note: Two main-spring barrels are used, lower right, one large and one small. This system affords a greater operational time, “reserve de marche”, than a single barrel and more consistent time keeping.

The barrel and center wheel bridge prior to application of “Cote-de-Geneve” (Geneva waves).

The same bridge after Cote-de-Geneve decoration and rodium plating.

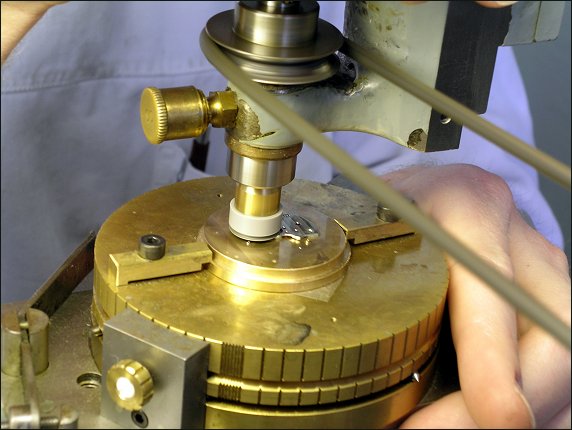

A machine for Cote-de-Geneve decoration.

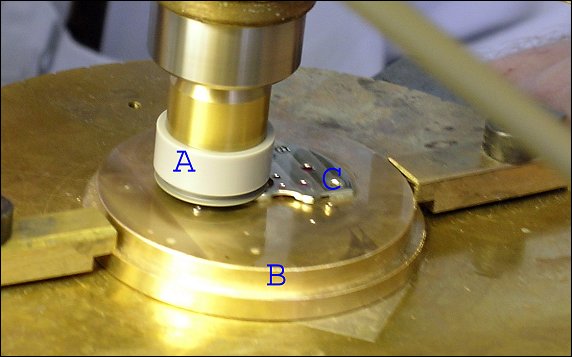

Application of the Cote-de-Geneve is accomplished using a machine fitted with a wooden (or in some cases plastic) lap. The lap “A” is a cup shaped disk charged with a mild abrasive mixed with light oil rotating at a medium speed of several hundred revolutions per minute. The bridges “C” are mounted on a fixture-plate “B”. The lap is lowered to gently touch the bridge surface and slowly moved in a straight line allowing the lap to create each stripe of arcs. The lap is lifted, the bridge is indexed according to the width of stripe desired, and another stripe is applied until the surface of the bridge is complete.

The fixture-plate is keyed to hold each individual bridge in the same orientation as when they are attached to the main plate. This manner of grouping assures that the stripes on each bridge will align perfectly with the stripes on the other bridges since each is bridge is decorated individually due to minor differences in height that could result in imperfections.

Click here for a short video showing Cote-de-Geneve being applied - 17.2 mb (Requires the QuickTime player)

A finished “Classic” movement ready to be fitted with its case. Note: The Cote-de-Geneve is perfectly aligned from bridge to bridge and the main-plate spotting adds a nice contrast to the stripes. The sapphire winding rotor is not assembled with the movement until after the movement has been cased due to the possibility of breakage during the casing operation.

The Vianney Halter “Classic” with patented sapphire winding rotor.

Lets have an informal look around the Vianney Halter ateliers…………

Stewart Lesemann making screws on the Leinen micro-lathe using a stereo microscope.

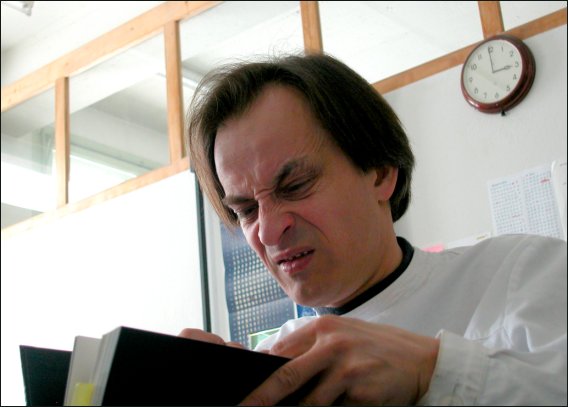

Mark Schmidt at the bench (is it lunch time already?)

An S.I.P. jig bore machine for making very precise holes. Big is better, even in watchmaking!

A Deckel milling machine with rotary table.

Some instruments and tools in Vianney’s office. He has an addiction to old and interesting vacuum tubes (center).

And, what was that word in English?

Click here to return to the TZ Independent Horology Forum to discuss or leave comments about this article.

© Ron DeCorte 2004, All rights reserved

|