|

A Visit With Peter Speake-Marin By Ron Decorte April, 2004

A visit with Peter and Daniela Speake-Marin is always a pleasure. The warmth of their hospitality makes me feel like an old friend... or maybe just old. Their youthful enthusiasm for what they do is stimulating, and it's a reminder of what the art of watchmaking is supposed to be. I should point out that Peter and Daniela operate their watchmaking business as a team, Peter is the watchmaker/designer and Daniela is the business manager and point-person for their work. Located on the shore of Lac Leman (Lake Geneva) in the small town of Rolle about 40 KM north of Geneva, the Speake-Marin atelier, “The Watch Workshop”, is modest and well equipped with modern and vintage tools-of-the–trade. The view of the lake and mountains makes a comfortable place for their work, and my three-day visit. Peter and Daniela are proud of their business independence. There have been ample offers for them to take investors into their business and participate in the mass production of watches, but they have refused all such offers. “We want to grow slowly in a well managed manner, we will probably never make thousands of watches but this isn’t an issue for us” says Peter. As a watch restoration expert in London, Peter developed his skills and a deep appreciation for the past masterpieces he was entrusted. After moving to Switzerland, and a short stint in world of modern production practices, Peter decided to make his own mark in watchmaking by drawing on his past with an eye for the future. As Peter says, “I want my watches to outlive me, I want someday for a watchmaker to be specializing in antiques and looking at one of my pieces the way I looked at some of the pieces I once worked on”. Prior to my visit I spoke with Peter about a suitable watch to feature in my documentary article. It was decided that his first watch, a pocket tourbillon, would make a good starting point. Peter’s pocket tourbillon is the creative result of his skills and imagination, one of a kind. As Peter said, “this is my Foundation Watch, the foundation for all my work since”. We eventually decided to include some pictures of his latest watch “Piccadilly” as a reference. It’s always interesting to see how a personal piece of art evolves as an idea and into reality. Examining the small bits and pieces is a great way to gain insight into that artistic process.

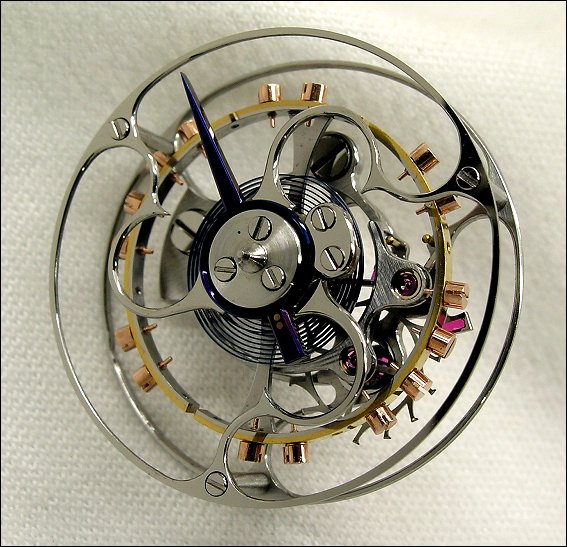

An expertly crafted pocket watch, with one-minute tourbillon, front and center stage.

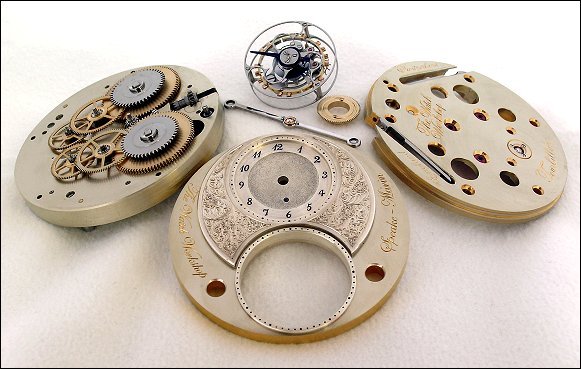

Peter took the unusual approach of using two mainspring barrels and two complete trains of wheels to deliver power to the tourbillon cage. You can see the barrel arbors and ratchet wheels, one to each side of “The Watch Workshop”. The second and third wheels follow symmetrically on each side of the watch leading to the tourbillon cage located by the diamond end stone in the lower center. Just below “The Watch Workshop” is a jewel for the center pinion carrying the minute hand on the opposite side. This is very practical from an engineering standpoint. Most tourbillions, eventhose with two mainspring barrels, use only one train of wheels to conserve space and manufacturing resources.

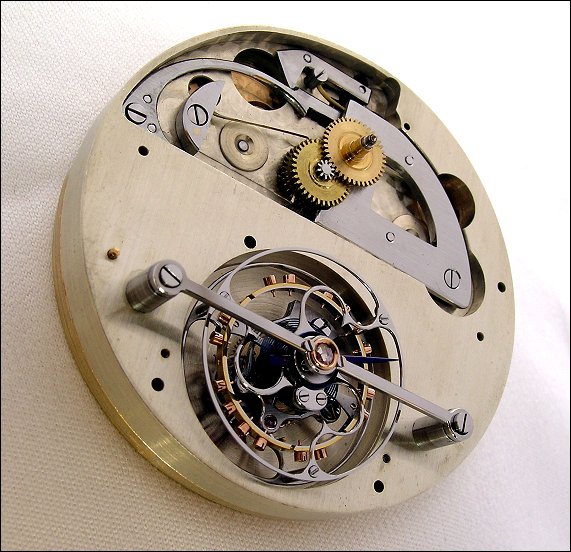

Some pictures of the tourbillon, with and without the dial. The regulator (in blue) serves as the second’s hand, very clever! Notice that diamond end stones (cap jewels) are used.

The tourbillon cage extracted from the watch. The cage is especially light and spidery, and there’s good reason for this approach. In a tourbillon watch the cage, and all its components, must be accelerated and then decelerated 5 times each second (if the watch is making 18,000 beats per hour). A heavy cage would require a lot more energy and would also contribute to erratic timekeeping at the lower end of the power cycle (when the main spring(s) is almost exhausted). This tourbillon cage and components are first rough machined using a precision pointer (jig bore) and then completely hand finished.

Under the dial. The hour and minute hands are positioned up towards the top of the watch to make room for a large tourbillon cage.

The main components of the watch. On the left is the main plate showing both mainspring barrels and both trains of wheels, identical.

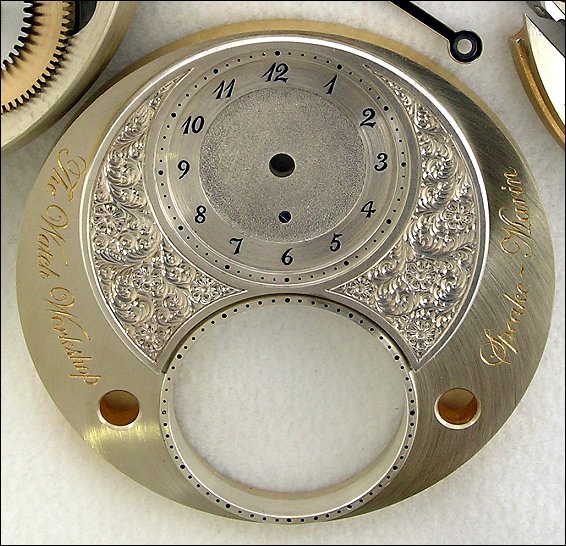

The dial is completely hand engraved. Lets zoom in for a closer look at the details…………

The main plate of the dial is German-silver, the upper center section is solid silver held in place by two invisible pins and one screw (just above the 6), and the solid silver seconds chapter ring is pressed into the main dial plate. Details of this dial can be seen in Peter’s more recent watches such as the silver dialed Piccadilly below.

Peter at the bench, no he isn’t sleeping, he just makes it look so easy!

Piccadilly in 18K yellow gold. Notice the shape of the auto-winding rotor is reminiscent of the pocket watch tourbillon cage.

Click here to visit Peter's official website Contact Peter at speake_marin@bluewin.ch

To leave comments or questions, or to join in a discussion about this article, please visit TimeZone's AHCI & Independent Watchmakers Forum.

Here are a few technical definitions that might be helpful: Tourbillon: Invented in the Abraham L. Breguet workshops more than two hundred years ago. The objective being to equalize positional errors in the escapement by rotating the entire escapement around a central axis. Historically a tourbillon makes its rotation once per minute, but in some cases in only a few seconds to more than one minute. Another adaptation of the tourbillon principal is the Carrousel used almost exclusively by English watchmakers. A carrousel is generally slower in its rotation, ranging from about 6 minutes to more than an hour per rotation. Although not as exciting to the eye, many time keeping prizes have been held by carrousel watches proving its merit. Diamond end stones: An end stone (cap jewel) affords a much greater reduction in friction as compared to a simple hole jewel in that only the very smallest tip of the pivot (shaft) is allowed to contact a flat surface rather than the shoulder of the pivot riding on the diameter of the hole jewel. Historically diamond end stones were used only in marine and pocket chronometers because of their hardness and durability, not to mention the difficulty of working (shaping) diamond as compared to ruby or sapphire. Wheels: It’s common practice in watchmaking to refer to gears as “wheels” In most cases a “wheel” is comprised of a gear and a pinion with the gear being fixed to the pinion shaft. Generally speaking a wheel has more than 14 teeth (dents), and a pinion has 14 or fewer teeth (leaves).

© Ron DeCorte 2004, All rights reserved Exclusive internet rights licensed to TimeZone.com

|