Introduction

One of the considerations in purchasing a new mechanical watch is the movement (or ebauche) used in the watch. There has been much discussion and some confusion about seemingly similar outsourced movements being used in a variety of brands priced from a few hundred to many thousands of dollars. And there has been much discussion about the merits of buying a brand that makes its own movements vs. a brand that outsources its movements. Many of the watch companies do not make it easy for us. In reading their literature it is not always clear what the origin of the ebauche is and what changes, if any, they have made to the basic movement. Some brands even mask the fact that they use a stock movement by changing the name of it.

As a result, it is easy to think that all watches using one of these movements, such as a particular ETA movement, must be all alike. This is, in fact, what I believed when I first got interested in watch collecting, but I have learned that this is not the case. It was a simplification, much like saying all computers using a Pentium chip are the same. This report is the results of efforts to learn more about this subject.

I should make it clear that I am neither an expert in watch movements nor in their designs. I am a multi-degreed engineer with over thirty years of developing dozens of products, mostly with high mechanical engineering content. This has given me an appreciation of complex mechanical designs, engineering design philosophy, materials, assembly methods, costs, time to market, value, and some of the related business issues.

In researching this article I contacted several manufacturers to ask for more information about their use of outsourced movements. Most were reluctant to provide any specific information and referred me to their catalogs. The only serious response I received was from Rolf Schnyder, president of Ulysse Nardin, who graciously answered all questions, provided a wealth of information, and even loaned me samples of the movements, which were examined by a highly regarded watchmaker, Asim Gunalp of San Diego and myself.

In House and Sourced Movements

Why would a company use an off-the-shelf design at all? It takes years to make and fully test an entirely new caliber, with automatics taking considerably longer than handwound calibers. The investment is very high. For a company selling a few thousand watches a year it would make little sense to create an entirely new movement. Even Rolex, which can spread the cost of a new movement over hundreds of thousands of watches each year, continues to use older movements and rarely develops a new one. A company may prefer to use their design resources to design new complications rather than design entirely new movements. Having worked with very creative design engineers, they’re often more interested in accomplishing new design challenges than to do what’s already been done, but just in a different way.

Also, not every existing basic movement is suitable to accommodate the added complications and to drive the extra functions. Only the best and more substantial movements can drive the additional mechanisms, and these are usually not the thinnest movements. By using outside movements, the company has a choice of ebauches to select from, based on the added complications they are adding.

A number of companies, such as Patek, Lange, Rolex, Minerva, JLC, Zenith, and others have developed their own movements and continue to use them in new models. However, many other companies no longer have access to these movements and need either to develop a new movement from scratch, or source a movement or their components from one of the few companies that sell movements to other companies. These include ETA, Lemania, Frederic Piguet, and a few others. Due to the high cost of design, tooling, and the construction of manufacturing equipment, designing a new movement from scratch may not always be cost effective, particularly for a company that makes only a few thousand watches each year. With the enormous amount of testing a new movement must go through there would also be delays in bringing the watch to market. That would delay bringing the complications, as well.

There’s Outsourced and Outsourced

When one looks at the specifications of a watch using an outsourced movement, it is not always clear what the quality of the movement is, which makes it difficult to know exactly what we are buying. Below on the left is an image showing a normal stock 2892-A2 as ETA would deliver it to a company wanting to use it intact, and next to it on the right, a Ulysse Nardin Astrolabium movement, which has a very detailed and finished rotor and the gray 'dial plate' which drives the disk of the dial. The Astrolabium contains just a few parts from the ETA 2892-A2, only for its winding-mechanism. An ETA 2892-A2 consists of 81 parts before assembly. UN has indicated that it needs a real 'tractor' and strong movement to keep all the Astrolabium features running, which resulted in the selection of these proven parts. To complete the Astrolabium movement, UN added no less than 110 new pieces of their own unique design.

UN does not buy the ETA 2892-A2 intact, but just some of the parts, most of which are then refinished and combined with other parts made from scratch and sourced elsewhere. The solid gold skeletized rotor on the Astrolabium is a good example. It is a finely chiseled rotor made from scratch to replace the original ETA heavy metal oscillating weight. Because it is skeletized, it has extra gold added to the inside perimeter of the rotor, not visible from the back f the watch.

UN, Frank Muller, IWC, Daniel Roth, and other prestigious companies, not having access to their own ebauches, yet wanting to develop unique products with their own complications, follow this approach and outsource movements or parts. It turns out only a very limited number of movement manufacturers make them available to other companies. (ETA is the largest with the widest selection of models.) By using outside movements or components, the company can select those parts that best match their needs.

Other movements that are designed in-house are often covered by patents, which permit a company to have movements with exclusive features, which are not available for sale to other companies. Few new movements are created today, and there is no guarantee that they would be more reliable than what is available at a similar price. Lange has created some of the more recent movements that have been highly acclaimed, but at very high costs. Stock of old movements are nowadays difficult to find. When they are available they are usually available in a very limited number.

Wide Range of Outsourced Movements

It also should be noted that ETA and others make many types of calibers with different characteristics, different levels of accuracies and workmanship, different sizes, heights and capabilities. The ETA model used in a Swatch movement, for example, costs a fraction of the Cal ETA 2892-2A. To many manufacturers the ETA 2892 is considered one of the best for the purpose of adding new complications and has more than twenty years of history behind it. The standard movement ETA 2892, by the way, has a center second and no power reserve.

You can see an assortment of almost a dozen ETA movements in Watches, Volume 4 or Wristwatches 2000. ETA sells these as i) complete movements equipped with its balance wheel assembly regulated, ii) unregulated and iii) in kits of unassembled mechanical parts.

Some watch manufacturers often buy their own mainsprings, hairsprings and their own balance wheel assembly. These also come in many different levels of quality and pricing. The better the quality of the spring and balance wheel assembly, the more accurate the manufacturer can regulate and maintain the accuracy of the movement. All Swiss and German watch companies purchase hairsprings from Nivarox and balance wheel assemblies from FAR (Fabrique d’Assortiments Réunies); a few factories are capable of making some of their own escapements.

The manufacture can then choose to decorate and finish the movement in a number of ways, including gold or rhodium plating, polishing, faceting and/or angling the plates and bridges. This is basically cosmetic work but is very visible when opening the back or viewing it through a transparent back. The better companies finish, assemble and regulate their own movements, whether based on their own movements or parts purchased from others.

An entirely different class of watches use unmodified, fully pre-assembled, outsourced movements. Criticism of these brands is usually based not on performance, but on the poor price-value ratio. These companies do not add value to the movement, and they often disguise this fact by giving the movement a special designation. Yet these companies charge prices running to many thousands of dollars. For example, below is a several year old watch that had a $3500 list price and uses an off the shelf ETA 7750 with no further enhancements other than adding the brand name to the rotor.

Some More Examples

I had the opportunity to visit the Minerva factory in Switzerland last year and saw first hand how they produce watches using movements that have been in production for over 30 years. This company likely could not afford to develop new movements today. For their Pallidio DT model they utilize a standard ETA 7750 and add a unique dual time function. This is an example of a fine, small company leveraging off of a good movement, but adding their own developed complication to create a unique movement.

I also visited IWC and saw how they manufacture their watches using parts purchased from ETA. For example, the UTC and Mark XV are each based on the ETA 2892-2A ebauche that goes through nearly complete remanufacture, and in the case of the former, adds an entirely new complication with a unique way of displaying a second time zone. You can see the complex mechanism created by going to the IWC site

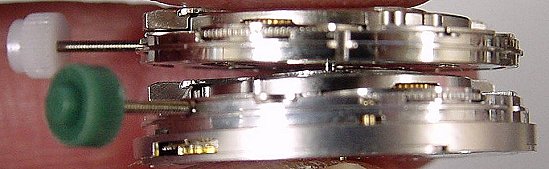

Ulysse Nardin takes a similar approach in their Big Date GMT, buying parts from ETA, refinishing many of these parts, and developing their own bridges. They then add their complications, which are the patented big date mechanism and the unique hour hand advance mechanism. Below is an image showing an edge view of the UN Big Date GMT movement (bottom) and the standard ETA 2892-2A (top).

Although the GMT Big Date utilizes the ETA 2892-A2, it adds 72 uniquely designed parts. Likewise, their popular Marine Chronometer 1846, utilizes the 2892 and adds 51 unique parts. Designed by Ludwig Oechslin, the new movement adds the small second hand at 6 o’clock and the power reserve, to develop a unique design.

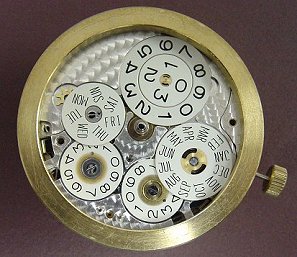

The movement used in the UN Perpetual Ludwig is shown below. You can recognize this movement from the various discs on top of the movement and the very refined white gold rotor with the hand-enameled UN logo on the back.

In the case of the UN Ludwig Perpetual, only a gear train was used intact, purchased from Lemania; all the other parts were made from scratch or modified. This movement doesn't use any ETA parts. The main plate is entirely developed by Ulysse Nardin and cannot be used in the Lemania caliber.

These added functions or transformations require space to house all the extra parts. A normal 2892 has a height of 3.60 mm, the GMT Big Date movement is 5.35 mm, and the Marine Chronometer 1846 is 5.10 mm.

In all of these movements with complications, the extra parts are added to the topside of the movement underneath the dial (where the extra functions are observed), they are not visible by looking at the bottom side of the movement (rotor side). Hence these models may look similar when peering through the rear sapphire window but are substantially different when viewed from the top and edge.

Improving the aesthetics of a movement can cost many times the price of the basic movement or ebauche. Custom gold or platinum rotors made in small quantities can cost hundreds of dollars each. Hand decorating, anglage, and gold or rhodium plating add to the cost as well. Beyond aesthetics, hand finishing, assembly, regulating and testing also add substantial value to a movement.

Summary

There are a range of movements of varying quality and complexity including:

A) off the shelf movements purchased from a movement company and used as is with no changes;

B) movements developed completely in-house, sometimes with added complications that are also often developed in-house;

C) movements with some parts from an outsourced movement combined with in-house designed parts, often used to create new complications.

My personal choice in watch collecting is to focus on B) and C) which provide examples of creativeness, originality and unique new design accomplishments. These complications combined with high quality cases and dials, are what makes these objects so interesting to me. It is one of the few product areas that combine both artistry and engineering excellence with a long history of product evolution into something that is so personal. A company using some sourced parts to create an individual and unique mechanism still requires strong capabilities in design and innovation.